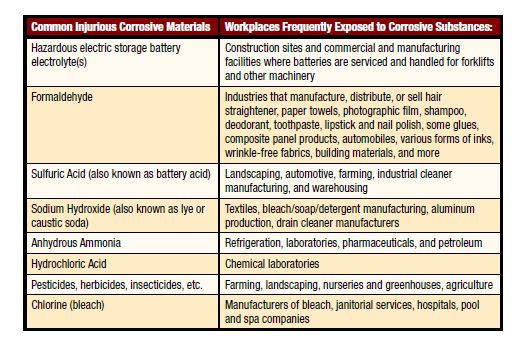

As the standard states an eyewash and or safety shower would be required where an employee s eyes or body could be exposed to injurious corrosive materials.

Eyewash standards and guidelines for the workplace.

Ansi z358 1 recommends a flow of 0 4 gpm also at 30 psi.

3 definitions combination unit.

The ansi z358 1 eyewash standard was first implemented in 1981.

This standard ansi z358 1 is intended to serve as a guideline for the proper design certification performance installation use and maintenance of emergency equipment.

These guidelines apply to all emergency safety showers and eyewash stations throughout the university.

The standard was modified in 1990 1998 2004 2009 and 2014.

Drench showers eyewash eye face wash portable eyewash and combination eyewash drench shower units.

National standards institute ansi has established a standard covering emergency eyewash and shower equipment.

Osha refers employers to the american national standards institute ansi and the international safety equipment association isea ansi isea z358 1 american national standard for emergency eyewash and shower equipment standard as a recognized source for such guidance.

File a complaint asking osha to inspect their workplace if they believe there is a serious hazard or that their employer is not following osha s rules.

Review records of work related injuries and illnesses.

Workers use eyewashes face washes and showers to flush chemicals and debris out of their eyes and off their bodies.

Equipment that falls under this standard includes.

The nozzles should be at least six inches from any obstruction and mounted between 33 and 45 inches above the floor.

The occupational safety and health administration osha requires eyewashes and emergency showers for workers who could be exposed to corrosive chemicals in the workplace.

Eyewash stations target just the eyes and therefore have a lower flow requirement.

The purpose of these guidelines is to outline the requirements for the inspection use and maintenance of mergency e safety showers and eyewash stations.

How eyewash and emergency showers help prevent long term worker injuries.

An eyewash gauge should be used to verify and test the flow pattern.

If none of the materials used in this work area is an injurious corrosive chemical as indicated by the material safety data sheet msds for each product then an emergency eyewash or.

2 code of practice first aid in the workplace this code of practice on first aid in the workplace is an approved code of practice under section 274 of the work health and safety act the whs act.